When it comes to operating a 4-stroke lawn engine, the fuel mixture plays an important role in maintaining performance and long lived. While it’s necessary to use the correct fuel to assure the engine operation, many people wonder whether using mix gas will harm a 4-stroke mower engine.

Will mixed gas hurt a four-stroke engine? Yes, if you add mix gas to a 4-stroke engine in high quantities, it will affect the lawn mower spark plug and reduce the mower’s performance, but if you add it in small quantities, it will not affect that much.

In this article, we will discuss the potential effects of mixed gas on a 4-stroke engine and provide insights into its performance, faithfulness, and life span. By understand the impact of mixed gas, you can make quick decisions regarding the fuel you use and take the essential steps to keep your mower engine running smoothly.

What’s the Difference Between 2-Stroke and 4-Stroke?

The differences between two-stroke and four-stroke lawn mower engines are related to their operating cycles, structures, fuel quantities, and features.

Here we discuss some points in detail:

Operating Cycle:

Two-Stroke Engine: The two-stroke engine used in lawnmowers completes its power cycle in two strokes of the piston—compression stroke and the power stroke. The intake and exhaust functions are combined in one stroke.

Four-Stroke Engine: The four-stroke engine used in lawnmowers completes its power cycle in four strokes of the piston—intake stroke, compression stroke, power stroke, and exhaust stroke. Each stroke is dedicated to a specific function.

Construction:

Two-Stroke Engine: Two stroke engines used in lawn mowers generally come in simpler designs with fewer moving parts. They lack valves, and instead they use ports for the intake and exhaust processes. Lubricating oil needs to be mixed properly with fuel for engine lubrication.

Four-Stroke Engine: Four stroke engines used in lawn mowers have a more difficult design with extra components such as valves, camshafts, and an excellent lubrication system. They have separate compartments for fuel intake, compression, combustion, and exhaust.

Fuel Requirements:

Two-Stroke Engine: Two stroke engines used in lawn mowers require a mix fuel of gasoline and oil. The oil roles as a lubricant for the engine since there is no separate lubricant system.

Four-Stroke Engine: Four-stroke engines used in lawn mower generally run on pure gasoline. They have a distinct lubrication system that uses engine oil to keep the moving parts properly lubricated.

Power Output:

Two-Stroke Engine: Two-stroke engines used in lawn mowers can produce high power-to-weight ratios and are known for their lightweight and solid design. They deliver more power per unit of logical shift

Four-Stroke Engine: Four-stroke engines used in lawnmowers are generally more fuel-efficient and supply smoother power. They may have a larger logical shift to generate the same power as a two-stroke engine.

How 4 stroke engine working ?

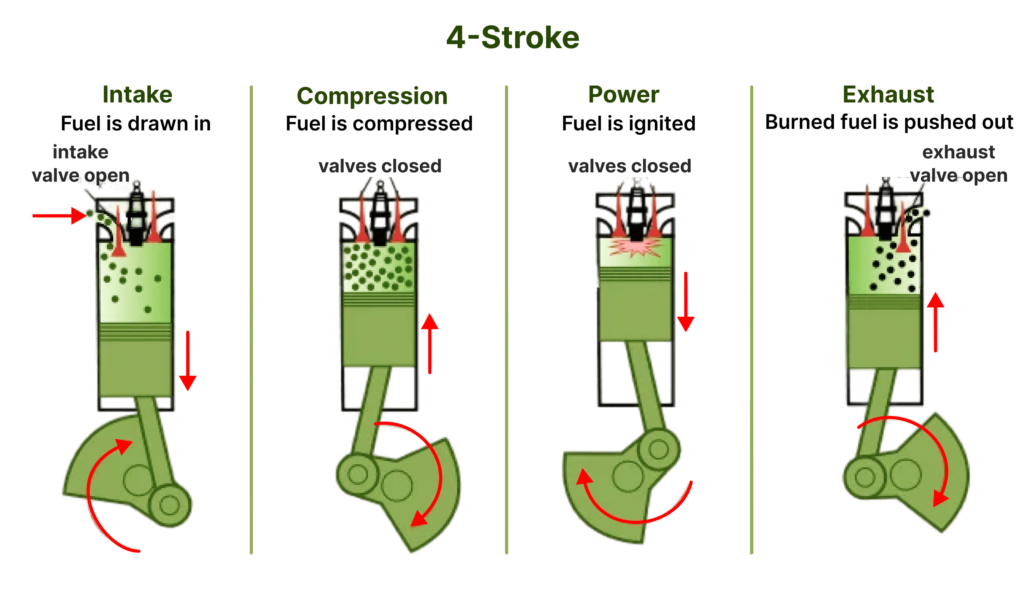

A four-cycle engine, also known as a four-stroke engine, and this working in four distinct steps.

Here’s a brief explanation of how a 4-cycle engine works:

Intake Stroke: Vacuum is created in the cylinder during the intake stroke when the piston falls. When the intake valve opens, the mixture of air and fuel enters the combustion chamber. Throughout this stroke, the piston stays at the cylinder’s bottom.

Compression Stroke: The intake valve goes close and the piston moves upward, compressing the air fuel mixture. and this compression raises the temperature inside the cylinder.

Power Stroke: At the top of the compression stroke, a spark plug ignites the compressed air-fuel mixture. The resulting combustion causes a rapid expansion of gases, forcing the piston back down. The downward motion of the piston generates power, which is delivered to the crankshaft.

Exhaust Stroke: After the power stroke, the piston returns to its starting position while the exhaust valve opens. The piston’s upward motion forces the gasses that have burned outside of the cylinder and into the exhaust system. This gets the cylinder ready for the next intake stroke.

One entire operational cycle of a 4-cycle engine consists of the four strokes of intake, compression, power, and exhaust. The cycle continues as long as there is fuel, air, and a spark. In comparison to two-stroke engines, this design allows for more efficient and clean combustion, making 4-cycle engines popular in vehicles, lawnmowers, motorcycles, and a number of other applications.

How 2 stroke engine working ?

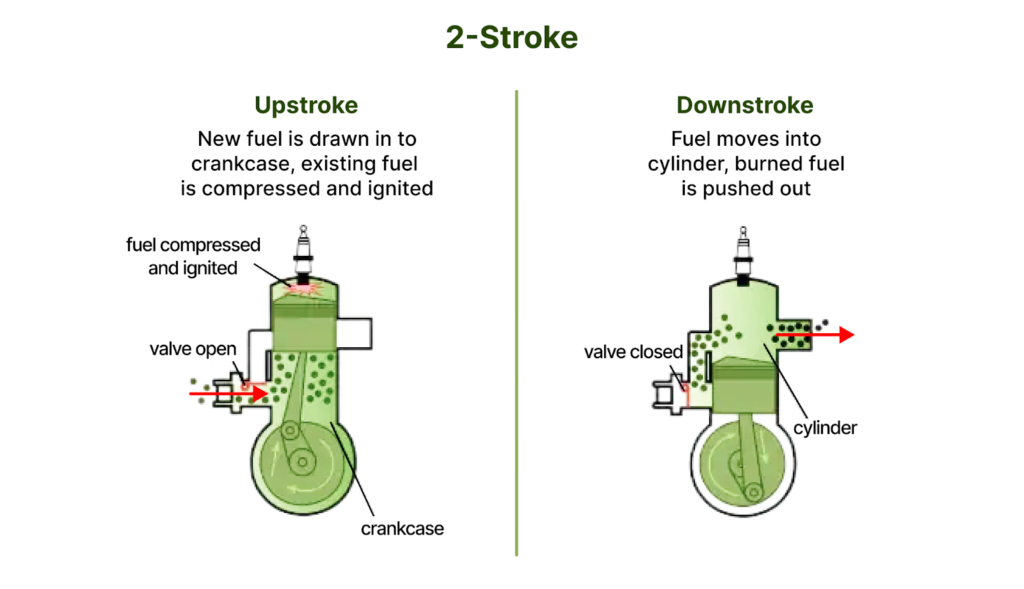

Two-cycle engines, often known as two-stroke engines, are widely used in a variety of applications, including chainsaws, lawnmowers, and motorcycles.

Let’s look at how these engines function now!

Consider this: a small powerhouse brimming with efficiency Two-cycle engines are designed to complete a power cycle in just two piston strokes, hence the name. These are referred to as the intake/compression and power/exhaust strokes.

During the intake stroke, a mixture of fuel (usually petrol) and oil is drawn into the engine’s cylinder as the piston swings downward. Through ports, which are perforations towards the bottom, this mixture enters the cylinder. The apertures are closed when the piston falls by covering them.

The compression stroke occurs next. The fuel-air combination inside the cylinder is compressed as the piston goes higher. A spark plug ignites the compressed mixture, resulting in a controlled explosion. This explosion generates the force required to drive the piston down and produce power.

This is when things become interesting. Unlike four-cycle engines, two-cycle engines do not have a specific exhaust stroke. Instead, as the piston returns to the top of the cylinder, it exposes the exhaust apertures. This permits the burned fuel fumes to escape as fresh fuel mixture enters through the lower ports at the same time.

With the exhaust gasses expelled and the fresh fuel mixture in place, the cycle starts all over again. The piston moves back down, covering the lower ports and drawing in a new mixture. The upward movement compresses the mixture, followed by ignition and power generation. The process repeats in a continuous loop, providing a constant source of power.

It was kept in mind that two cycle engines require a precise fuel-to-oil ratio in order to maintain the internal components. Before being supplied to the engine, this oil-fuel mixture pre-mixed and stored in a separate tank

Why Two-Stroke Engines Need Mixed Gas?

Two-stroke engines and mixed gasoline, oh my! It’s a fascinating subject. Two-stroke engines, unlike four-stroke engines, do not have a separate lubricating system. Instead, they use a gasoline-oil combination for lubrication. This is when mixed gas enters the picture. When we say “mixed gasoline,” we mean a specified proportion of fuel (gasoline) and oil. This concoction performs two crucial functions. First, the oil in the mixture lubricates the engine’s moving components, decreasing friction and minimizing excessive wear and tear. Second, it functions as a coolant, dispersing heat from the combustion process.Without the oil in the mix, a two-stroke engine would quickly suffer from insufficient lubrication, leading to increased friction, overheating, and potentially severe damage. So, by using mixed gas, we ensure proper lubrication and cooling for the engine, enabling it to run smoothly and efficiently.

Why Four-Stroke Engines Not Need Mixed Gas?

Because four-stroke engines function on a different basis than two-stroke engines, they do not require blended petrol. The intake stroke of a four-stroke engine brings in a combination of air and fuel through the intake valve. During the compression stroke, the piston compresses this mixture. During the power stroke, the spark plug ignites the compressed mixture, causing gas expansion and driving the piston down. Finally, the combustion byproducts are expelled through the exhaust valve during the exhaust stroke. The engine may segregate the intake and exhaust processes using this cycle, guaranteeing that only air reaches the combustion chamber during the intake stroke. The four-stroke engine may be controlled by regulating the timing and distribution of gasoline via the fuel injection system or carburetor.

When choosing between a 2-cycle and 4-cycle engine, there are a few things to take into account. Each has benefits and drawbacks. The two-cycle engine, sometimes referred to as a two-stroke engine, is unique due to its more compact and tiny body. He is therefore appropriate for applications like portable power tools or tiny cars where weight and compactness are key factors. The 4-cycle engine, sometimes referred to as a four-stroke engine, uses less fuel and produces less emissions. Larger machines like cars, motorcycles, and lawn mowers frequently use this engine. Everything, though, depends on factors including power requirements, environmental concerns, and intended purpose. As a result, it is impossible to say for certain which is accurate.

When choosing between a 2-cycle and 4-cycle engine, there are a few things to take into account. Each has benefits and drawbacks. The two-cycle engine, sometimes referred to as a two-stroke engine, is unique due to its more compact and tiny body. He is therefore appropriate for applications like portable power tools or tiny cars where weight and compactness are key factors. The 4-cycle engine, sometimes referred to as a four-stroke engine, uses less fuel and produces less emissions. Larger machines like cars, motorcycles, and lawn mowers frequently use this engine. Everything, though, depends on factors including power requirements, environmental concerns, and intended purpose. As a result, it is impossible to say for certain which is accurate.

Which Is Better a 2-Cycle or 4-Cycle?

There are a few factors to consider when deciding between a 2-cycle and 4-cycle engine. Both have pros and cons. The 2-cycle engine, often known as a two-stroke engine, is special by its smaller and compact body. As a result, he’s suitable for applications where weight and compactness are important, like portable power tolls or miniature automobiles. The 4-cycle engine, commonly known as a four-stroke engine, on the other hand, is more fuel-efficient and less in pollutants. This engine is typically seen in bigger machinery like as lawn mowers, automobiles, and motorbikes. However, everything is dependent on considerations like as power needs, environmental concerns, and intended use. As a result, there is no conclusive answer as to which is correct. So lastly, choose which stroke engine will fulfill your requirements.

conclusion

In conclusion, we addressed the query “Will Mixed Gas Hurt A 4 Stroke Engine?” in this post. We also made an effort to address the most important queries. Additionally, avoid using mixed petrol in 4-stroke engines. Your engine will suffer damage, and it will run less efficiently. In order to preserve the life and best performance of your 4-stroke engine, it’s crucial to use the recommended fuel and oil combination from the manufacturer. We hope that this article will make it easier for you to understand their recommendations.